The use of a Dual Drive system with two motors guarantees high force for the heaviest duty operations, exploiting the power of both motors delivering their maximum output in the same direction. For higher precision work the preload value is increased automatically to obtain the maximum accuracy.

The Dual Drive system has lower energy consumption than linear motors and it does not require dedicated cooling systems.

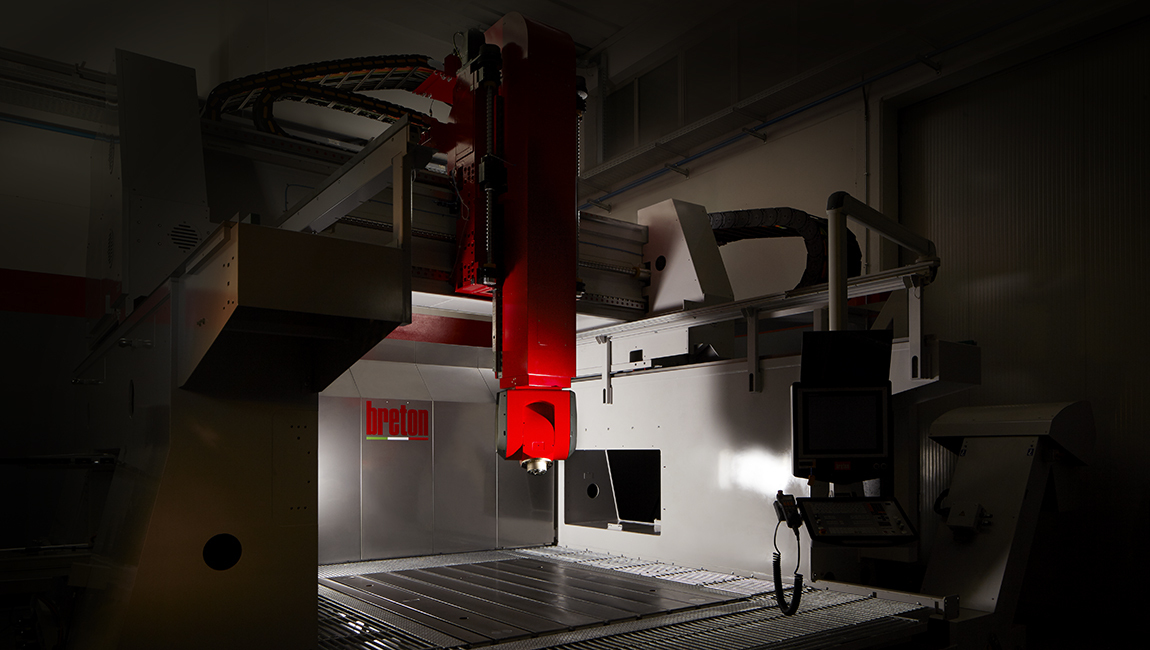

High dynamic and high precision 5 axis vertical gantry machining centre

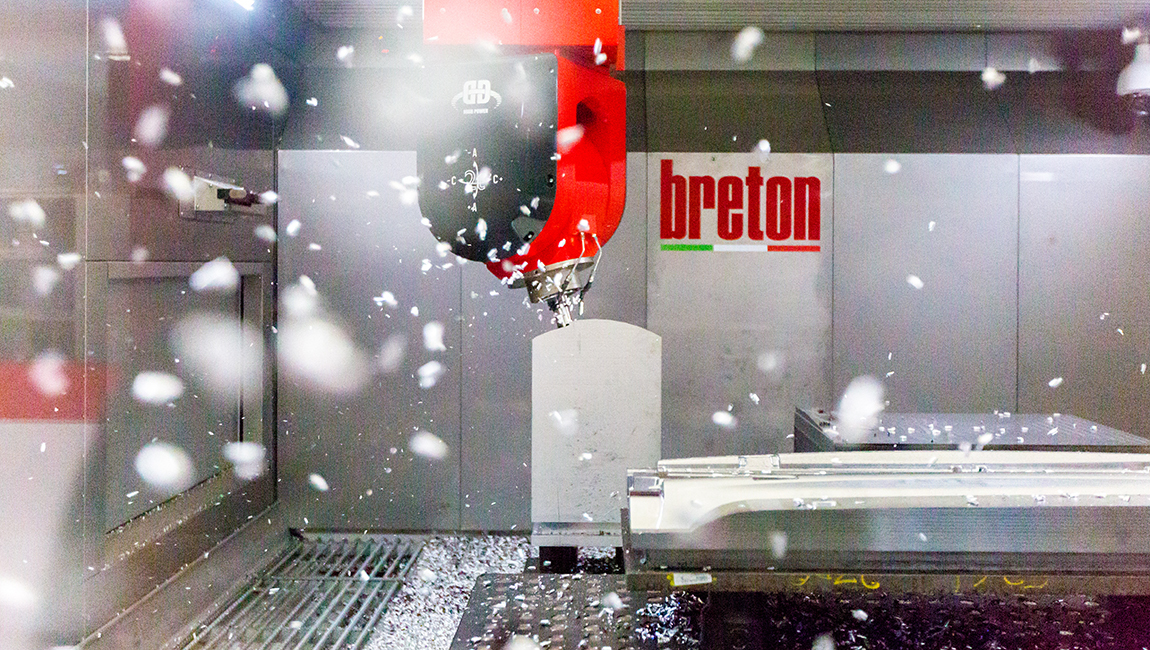

The development of this machining centre was based on careful technical choices that combine thrust and robustness with dynamics and precision for perfect performance in hi-feed roughing, semi-finishing and finishing of medium-large workpieces in steel, lightweight alloys, and special composites.

Breton Matrix E2

Reasons why

Created for mould & die makers, but perfect for aerospace too

Matrix is a machining centre that combines the robustness and thrust required for roughing operations with the dynamics and precision needed for finishing. A stable and robust base that is also extremely dynamic, configurable with a broad range of components and accessories in order to handle entire machining processes in a large number of sectors.

The robust sandwich structure columns in arc welded and stabilised steel bring exceptional structural stiffness and a high level of vibration damping, both factors that translate into better surface finishing of machined workpieces and longer life of tools and components subject to wear. To guarantee surfaces with a superior finish and greater precision, Matrix E2 exploits High Dynamics and Thermal Shield technologies, both of which are exclusive to Breton. All these factors combine to make this machining centre ideal for the world of large size moulds and dies, but with the correct configuration it is also perfect for machining work in the aerospace sector or in general precision engineering.

Materials

Processes

Industries

Applications

Technologies

Numerical control

Technological highlights

Other versions of Breton Matrix E2

Version comparative table

| Matrix E2 1100 K25 | Matrix E2 1100 K40 | |

|---|---|---|

"X" axis travel | 2500 mm | 4000 mm |

"Y" axis travel | 2500 mm | 2500 mm |

"Z" axis travel | 1100 mm | 1100 mm |

"X" axis rapid feed rate | 50 m/min | 50 m/min |

"Y" axis rapid feed rate | 50 m/min | 50 m/min |

"Z" axis rapid feed rate | 40 m/min | 40 m/min |

"A" axis travel | -105 - 120 ° | -105 - 120 ° |

"A" axis rapid speed | 30 rpm | 30 rpm |

"C" axis travel | continuo | continuo |

"C" axis rapid speed | 30 rpm | 30 rpm |

Dimensions of the workbench (width) | 1000 mm | 1000 mm |

Dimensions of the workbench (length) | 2000 mm | 2000 mm |